Designing Clamp Cranes for Narrow Workshops & Low Headroom

Most Important Takeaway

When working with narrow workshops and low headroom, the main challenge isn’t just lifting capacity—it’s how to fit a clamp crane safely and efficiently into a tight space while keeping operations smooth. Proper planning, customized design, and understanding the site limitations are key to avoiding costly mistakes and downtime.

Key Takeaways

Here’s what this guide will help you solve:

- Space limitations solved: How to design clamp cranes that fit narrow workshops without compromising performance.

- Low headroom challenges addressed: Adjustments for hoist height, trolley size, and girder profile to ensure clearance and safe operation.

- Clamp compatibility clarified: Selecting the right clamp type and size so it works within restricted space.

- Workflow and safety issues: Planning crane paths and installation to avoid collisions and maintain productivity.

- Maintenance access considered: Designing cranes for easy inspection and service in confined environments.

- Cost vs. feasibility: Balancing customized solutions and standard equipment to get the best ROI.

Workshop Constraints

Every workshop is different, and when you have narrow spaces combined with low ceilings, installing a clamp crane can become a real puzzle. You can’t just pick a standard crane and hope it fits. First things first: measure everything. Take note of the width, height, and any overhead equipment that could get in the way. Even small things like lights, ducting, or pipes can interfere with crane travel. And don’t forget about doors, gantries, or structural pillars—these are often overlooked but can cause big headaches later.

- Width of the workshop: This directly determines the crane span. A narrow workshop means your trolley travel and crane beam must be carefully planned so the crane can move without hitting walls or machinery.

- Ceiling height / headroom: Low ceilings limit the hook approach, hoist type, and girder profile. You may need a low-headroom hoist or compact trolley to make everything fit safely.

- Obstructions: Overhead lights, ventilation ducts, fans, and piping can block crane paths. Map out all these obstacles before designing the crane.

- Workflow layout: Study how materials are moved around the workshop. Knowing the flow helps prevent collisions, reduces the risk of bottlenecks, and ensures operators can work efficiently.

A practical tip: walk the workshop as if you’re the crane, tracing every movement from start to finish. This often reveals hidden issues that drawings alone won’t show. Understanding these constraints upfront makes the difference between a crane that works smoothly and one that constantly gets in the way.

Clamp and Hoist Considerations

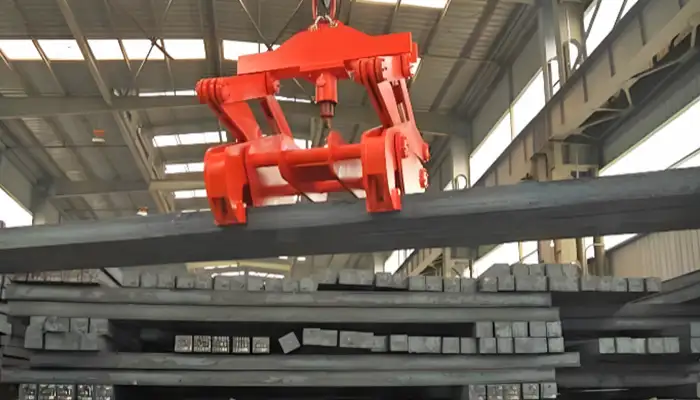

In low-headroom and narrow workshops, the clamp and hoist are usually the tallest parts of a crane system, so getting them right is crucial. If the clamp is too big or heavy, it can reduce clearance or overload the crane. Choosing the proper hoist and clamp isn’t just about lifting capacity—it’s about fitting into the space, working efficiently, and keeping operations safe.

- Clamp type: Mechanical clamps are simple, reliable, and ideal for repeated lifts of uniform materials like billets or slabs. Hydraulic clamps are better for heavier loads or irregular shapes, offering adjustable gripping force and smoother handling. Choosing the right type ensures the clamp fits your material handling needs without wasting space.

- Clamp weight and size: A heavy or bulky clamp can reduce headroom and stress the crane rails. Make sure the clamp’s weight and dimensions are compatible with both the crane capacity and the workshop layout. Always allow extra clearance to prevent the clamp from scraping ceilings or overhead equipment.

- Hoist selection: Low-profile hoists are specifically designed for tight vertical spaces. They can handle rated loads without requiring additional headroom. Consider hoists with compact trolleys that fit easily under girders in narrow workshops.

- Operational efficiency: Adjustable or quick-release clamps can significantly reduce lift time. In workshops where space is tight, being able to grip, release, or swap materials quickly improves workflow and reduces the chance of collisions or downtime.

A practical tip: always check the combined height of the hoist and clamp against your available headroom before finalizing any purchase. Even small miscalculations can lead to costly adjustments during installation.

Structural and Mechanical Adjustments

Installing a clamp crane in a narrow workshop with low headroom isn’t just about picking the right crane type or hoist. You often need to rethink the crane’s structure to make everything fit safely and efficiently. Small design changes can save headroom, reduce stress on rails, and improve overall workflow.

- Girders: Using low-profile or tapered girders helps reduce vertical space requirements. These designs maintain strength while allowing more clearance between the crane hook and the ceiling, which is especially important in workshops with limited headroom.

- Runway beams: Overhead or side-mounted runway beams can make a big difference in tight spaces. Overhead beams keep the floor clear, while side-mounted beams can work when ceiling height is limited. Both need careful alignment to avoid collisions with machinery or other cranes.

- Trolley and hoist integration: Compact trolleys and hoists are key for maintaining crane speed and safety in confined spaces. A well-integrated system prevents the hoist or clamp from hitting obstacles while keeping lifts smooth and precise.

- Materials: Choosing strong yet lightweight materials for girders, trolleys, and end carriages reduces overall crane weight and lessens stress on the runway rails. This is crucial for narrow workshops where excessive load could cause structural issues or require expensive reinforcements.

A practical tip: before finalizing designs, mock up the crane path or use 3D modeling to check clearance and movement. Seeing how the crane, hoist, and clamp operate together in the actual space can prevent costly modifications during installation.

Safety and Maintenance

Working in narrow workshops with low headroom doesn’t mean you can cut corners on safety. In fact, tight spaces make planning for safe crane operation and maintenance even more critical. A well-designed crane not only fits the space but also keeps operators and equipment protected.

- Clearance and collision prevention: Always check that the crane, clamp, and hoist have enough clearance to move freely. Map out paths to avoid walls, machinery, overhead pipes, or other cranes. Even small miscalculations can lead to collisions and downtime.

- Overload protection: Install reliable overload devices to prevent lifting beyond the crane’s rated capacity. This protects both the crane structure and the operators, especially when clamps handle heavy billets or slabs in confined areas.

- Inspection and maintenance access: In tight workshops, space for maintenance is limited. Modular or removable components make it easier to inspect and service hoists, trolleys, and clamps without taking apart the entire crane. Routine checks should be planned around crane accessibility to avoid long production stoppages.

A practical tip: create a maintenance checklist before installation. Include daily, weekly, and monthly inspections for hoists, clamps, rails, and safety devices. Planning ahead saves time and prevents unexpected breakdowns in narrow and low-headroom workshops.

Conclusion

Designing clamp cranes for narrow workshops and low headroom isn’t just about picking a crane off the shelf. It’s about smart planning, practical adjustments, and paying attention to the details that really matter. By carefully reviewing your workshop’s space constraints, choosing the right crane type, matching clamp size, and making structural adjustments, you can create a crane system that works safely and efficiently every day.

Working closely with experienced crane manufacturers is essential. They can help tailor the crane to your layout, advise on low-profile hoists or compact trolleys, and ensure the crane integrates smoothly into your workflow. Don’t overlook maintenance and long-term operational needs—planning for inspections, component access, and safety checks upfront saves time and prevents costly downtime.

In short, taking a practical, hands-on approach to crane design in tight spaces avoids surprises, maximizes productivity, and protects your investment. With the right design and planning, even a narrow, low-ceiling workshop can handle heavy materials safely and efficiently.